Sulphonic Acid

Understanding Sulphonic Acid

Sulphonic Acid, also known as sulfonic acid, is an organic compound characterized by the presence of a sulfonic functional group (–SO3H). It is widely used in detergent formulations as a surfactant and cleaning agent. Sulphonic Acid is valued for its excellent wetting, emulsifying, and foaming properties, making it an indispensable component in many cleaning products.

Applications in Detergent Chemicals

Sulphonic Acid serves several crucial functions in the production of detergents:

Surfactant: It acts as a surfactant in detergent formulations, reducing the surface tension of water and allowing it to penetrate and lift dirt and grease from surfaces.

Cleaning Agent: Sulphonic Acid exhibits strong cleaning properties, effectively removing stains, oils, and other contaminants from fabrics, dishes, and surfaces.

Emulsifier: It helps stabilize oil-in-water emulsions, allowing oil and grease to be dispersed in water for easier rinsing and removal.

Applications in Mines

Sulfuric Acid plays a crucial role in various aspects of mining operations, owing to its unique properties and versatile nature. Here are some primary applications of Sulfuric Acid within the mining sector:

Ore Leaching: Sulfuric Acid is widely used in hydrometallurgical processes for the leaching of metals from ores. It facilitates the dissolution of metal sulfides, oxides, and hydroxides to form soluble metal sulfate complexes, thereby aiding in the extraction and recovery of metals such as copper, nickel, uranium, and zinc from low-grade ores.

PH Adjustment: Sulfuric Acid is utilized in mineral processing operations to adjust the pH of process solutions. It serves as a pH modifier, allowing operators to control acidity levels in leaching, flotation, and precipitation processes, thereby optimizing mineral recovery rates and process efficiency.

Desulfurization: In the treatment of metal concentrates and by-products, Sulfuric Acid is employed for the removal of sulfur compounds, such as iron sulfides (pyrite) and arsenic sulfides, through oxidative leaching processes. It oxidizes sulfide minerals to soluble sulfate ions, thereby reducing sulfur emissions and environmental impact.

Electrowinning: Sulfuric Acid is used as an electrolyte in electrowinning processes for the extraction and purification of metals from leach solutions. It provides the necessary conductivity and pH conditions for electrodeposition, allowing metals such as copper, nickel, and zinc to be electroplated onto cathodes for subsequent refining and processing.

Water Treatment: Sulfuric Acid is employed in water treatment processes for the neutralization of alkaline mine water and the removal of contaminants such as heavy metals and metalloids. It reacts with alkaline compounds and metal hydroxides, forming soluble metal sulfate salts and water, thereby improving water quality and minimizing environmental impact.

Why Choose Pintchem?

-Quality Assurance: We adhere to stringent quality control measures to ensure that our Caustic Flakes, Lye, and Pearl meet the highest standards of purity and effectiveness, guaranteeing superior performance in detergent manufacturing.

-Reliability: With years of industry expertise, we’ve earned a reputation for reliability and consistency, delivering high-quality products on time, every time.

-Custom Solutions: We understand the unique needs of our clients and offer customizable solutions tailored to specific requirements, ensuring the perfect fit for your detergent formulations.

-Technical Support: Our team of experienced professionals provides comprehensive technical support, assisting with product selection, formulation optimization, and troubleshooting.

Contact Us

We would love to work with you!

Contact Barry:

Email: barry@pintchem.com

Tel: +27 79 526 5980

.

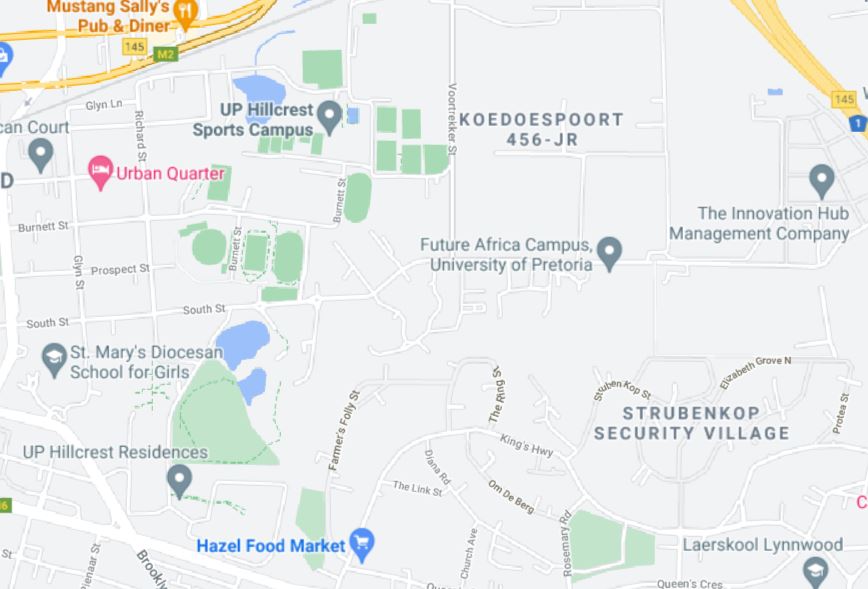

Physical Address:

4 Mount Hess Street, Midstream