Nitric Acid

Welcome to Pintchem, your trusted provider of high-quality chemicals for various industries, including detergent manufacturing. Our commitment to excellence and innovation ensures that our clients receive top-tier products tailored to their specific needs. Among our extensive offerings is Nitric Acid, a powerful ingredient with numerous applications in detergent production and beyond.

Understanding Nitric Acid

Nitric Acid, with the chemical formula HNO3, is a highly corrosive and colorless liquid with a sharp, pungent odor. It is one of the most important industrial chemicals, widely used in various industrial processes, including the production of detergents. Nitric Acid is valued for its strong acidic properties and its role as a key reactant in chemical synthesis.

Applications in Detergent Chemicals

Nitric Acid serves several crucial functions in the production of detergents:

PH Adjustment: It is used for pH adjustment in detergent formulations, ensuring the optimal pH level for effective cleaning and compatibility with different water conditions.

Cleaning Agent: Nitric Acid can act as a cleaning agent in certain detergent formulations, helping to remove stubborn stains and mineral deposits from surfaces.

Corrosion Control: In some formulations, Nitric Acid helps prevent corrosion by neutralizing alkaline residues and protecting metal surfaces.

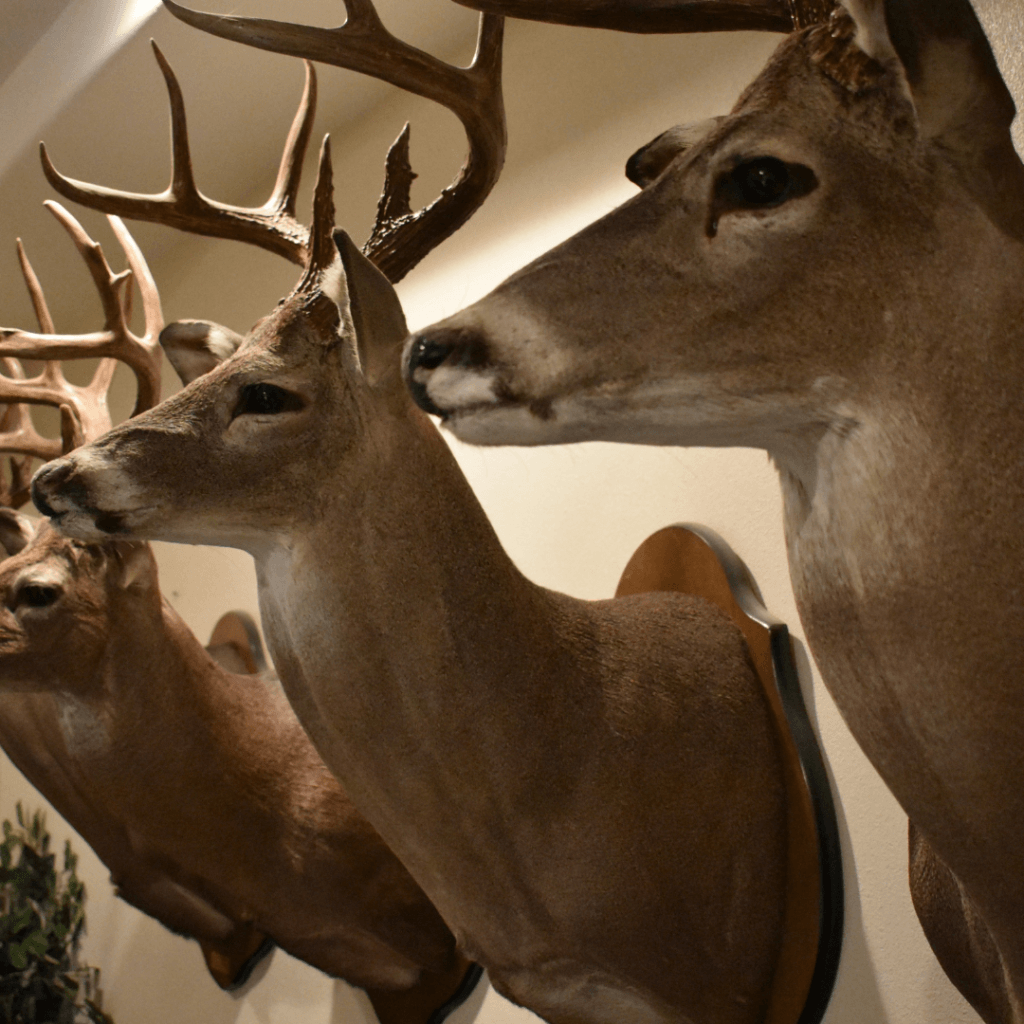

Applications in Taxidermy

Nitric Acid offers several key benefits and applications in taxidermy preservation:

Tissue Preservation: Nitric Acid is utilized to fix and preserve animal tissues, ensuring they maintain their natural texture and appearance. By denaturing proteins and inhibiting microbial growth, Nitric Acid effectively prevents tissue decay and degradation during the taxidermy process.

PH Adjustment: Proper pH levels are essential in taxidermy preservation solutions to optimize the preservation process. Nitric Acid is often used to adjust and stabilize the pH of these solutions, ensuring optimal conditions for preservation and preventing the growth of harmful microorganisms.

Degreasing Agent: Nitric Acid is also employed as a degreasing agent in taxidermy, removing excess fats and oils from animal hides and skins. This ensures thorough preservation and prevents the formation of rancid odors or unsightly blemishes on the specimens.

Applications in Tannery

In the tannery industry, Nitric Acid is employed for various crucial purposes:

Pickling Agent: Nitric Acid serves as an effective pickling agent in the preparation of hides and skins for tanning. Its acidic properties facilitate the removal of impurities and unwanted substances from the raw materials, ensuring a clean and uniform surface for further processing.

PH Adjustment: Nitric Acid is utilized for pH adjustment during the tanning process. Maintaining the appropriate pH level is essential for optimizing the effectiveness of tanning agents and ensuring uniform penetration of the tanning solution into the hides or skins.

Bleaching Agent: In certain tanning processes, Nitric Acid is employed as a bleaching agent to achieve desired color effects on leather. Its oxidative properties help lighten or alter the natural color of the leather, allowing tanneries to produce a wide range of leather products with distinct appearances.

Applications in Mines

Applications in Mining:

Nitric Acid plays a crucial role in several aspects of mining operations, owing to its unique properties and versatile nature. Here are some primary applications of Nitric Acid within the mining sector:

Explosives Production: Nitric Acid is a key ingredient in the manufacturing of explosives used for blasting in mining and quarrying activities. It serves as an oxidizing agent in the nitration of organic compounds, such as glycerol and ammonium nitrate, to produce explosives like dynamite, ANFO (ammonium nitrate/fuel oil), and emulsions.

Metal Leaching: Nitric Acid is utilized in hydrometallurgical processes for the leaching and extraction of metals from ores and concentrates. It is particularly effective in the leaching of base metals like copper, zinc, and nickel, as well as precious metals like gold and silver, by oxidizing metal sulfides and facilitating the dissolution of metal ions into solution.

Etching and Surface Treatment: Nitric Acid is employed in the mining industry for etching and surface treatment of metals and alloys. It is used to remove oxides, scale, and impurities from metal surfaces, preparing them for further processing, welding, or coating applications, thereby enhancing the quality and performance of mining equipment and components.

Cyanide Detoxification: Nitric Acid is utilized in cyanide detoxification processes to neutralize cyanide compounds generated in gold extraction operations. It reacts with cyanide ions to form less toxic cyanate and nitrate ions, thereby mitigating environmental risks associated with cyanide-containing wastewater and tailings.

Laboratory Analysis: Nitric Acid is commonly used in laboratory analysis and testing within the mining industry. It is employed for sample digestion, dissolution of minerals, and preparation of reagent solutions for chemical analysis techniques such as atomic absorption spectroscopy (AAS), inductively coupled plasma mass spectrometry (ICP-MS), and X-ray fluorescence (XRF).

Applications in Agriculture

Disodium Molybdate plays a vital role in agriculture, particularly in ensuring optimal plant nutrition and crop productivity. Here are some primary uses of Disodium Molybdate in the agricultural sector:

Molybdenum Fertilizer: Disodium Molybdate is used as a molybdenum fertilizer to supplement soil and plant molybdenum levels, especially in molybdenum-deficient soils. Molybdenum is an essential micronutrient required for nitrogen fixation in leguminous plants and plays a crucial role in enzyme systems involved in nitrogen metabolism and protein synthesis. Disodium Molybdate-based fertilizers are applied to crops, such as legumes, cereals, and cruciferous vegetables, to prevent molybdenum deficiency symptoms, such as yellowing of leaves and poor growth, and improve nitrogen utilization and crop yield.

Seed Treatment: Disodium Molybdate is utilized in seed treatment processes to enhance seedling vigor and promote early root development in crops. It serves as a molybdenum source for germinating seeds, ensuring adequate nutrient availability and uptake during seedling establishment. Disodium Molybdate-based seed treatments improve seedling emergence, root growth, and nutrient absorption, leading to improved crop performance and yield potential.

Foliar Application: Disodium Molybdate can be applied as a foliar spray to correct molybdenum deficiencies and alleviate stress in crops experiencing nutrient imbalances or adverse environmental conditions. Foliar applications of Disodium Molybdate provide a rapid and efficient means of delivering molybdenum to plants, allowing for quick correction of deficiency symptoms and improved plant health. Disodium Molybdate-based foliar sprays are commonly used in horticultural crops, such as fruits, vegetables, and ornamentals, to enhance yield, quality, and marketability.

Soil Amendment: Disodium Molybdate is used as a soil amendment to replenish depleted molybdenum levels and maintain optimal soil fertility for crop production. It can be incorporated into soil mixes or applied as a top dressing to correct molybdenum deficiencies in agricultural soils, ensuring adequate nutrient supply to growing crops and preventing yield losses associated with nutrient deficiencies. Disodium Molybdate-based soil amendments improve soil health, nutrient cycling, and crop nutrient uptake efficiency, contributing to sustainable agricultural practices and environmental stewardship.

Why Choose Pintchem?

-Quality Assurance: We adhere to stringent quality control measures to ensure that our Caustic Flakes, Lye, and Pearl meet the highest standards of purity and effectiveness, guaranteeing superior performance in detergent manufacturing.

-Reliability: With years of industry expertise, we’ve earned a reputation for reliability and consistency, delivering high-quality products on time, every time.

-Custom Solutions: We understand the unique needs of our clients and offer customizable solutions tailored to specific requirements, ensuring the perfect fit for your detergent formulations.

-Technical Support: Our team of experienced professionals provides comprehensive technical support, assisting with product selection, formulation optimization, and troubleshooting.

Contact Us

We would love to work with you!

Contact Barry:

Email: barry@pintchem.com

Tel: +27 79 526 5980

.

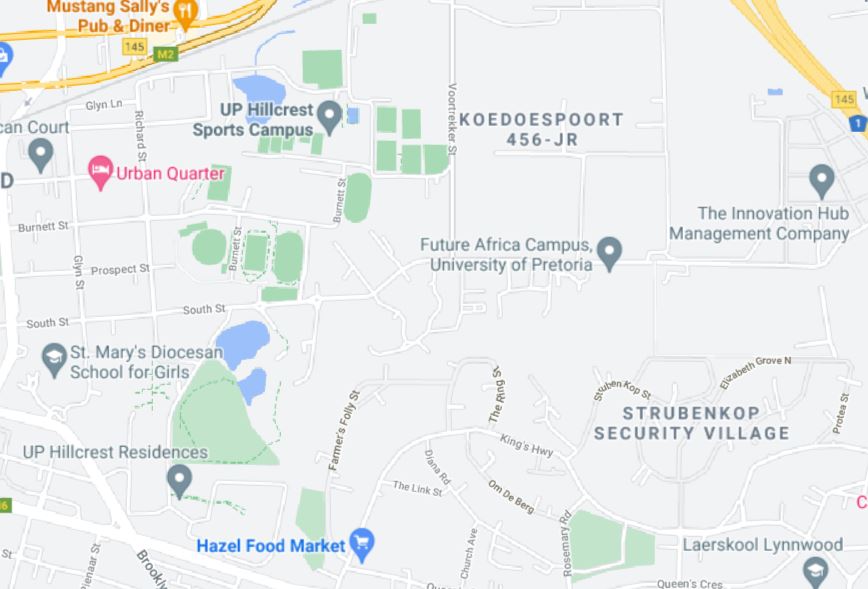

Physical Address:

4 Mount Hess Street, Midstream